Manufacturer Details

MATERIALS

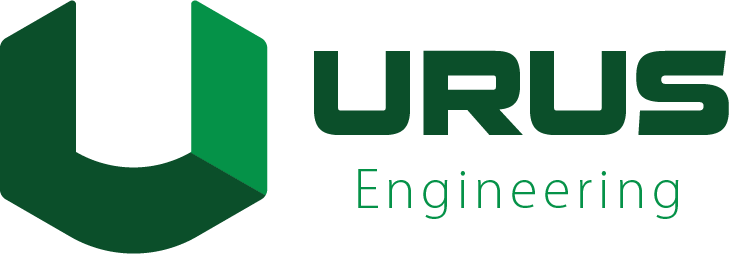

UNWINDER X 2

Pneumatic of Jumbo Roll Loading arms lifting

Pneumatic Fixing of Jumbo Roll Shaft

Manual Jumbo Roll Centering

Pneumatic Jumbo Roll Unwinder Belt Arm

Manual tension control (Automatic Option)

Jumbo Roll Limit switch Option

EMBOSSER

Rubber to Steel Embossing system

Manual Embossing Register Control adjustment

Manual Folder Register Control adjustment

Customized Full Embossing pattern

Chrome Plated Embossing Cylinder

FOLDER

Air vacuum folding system

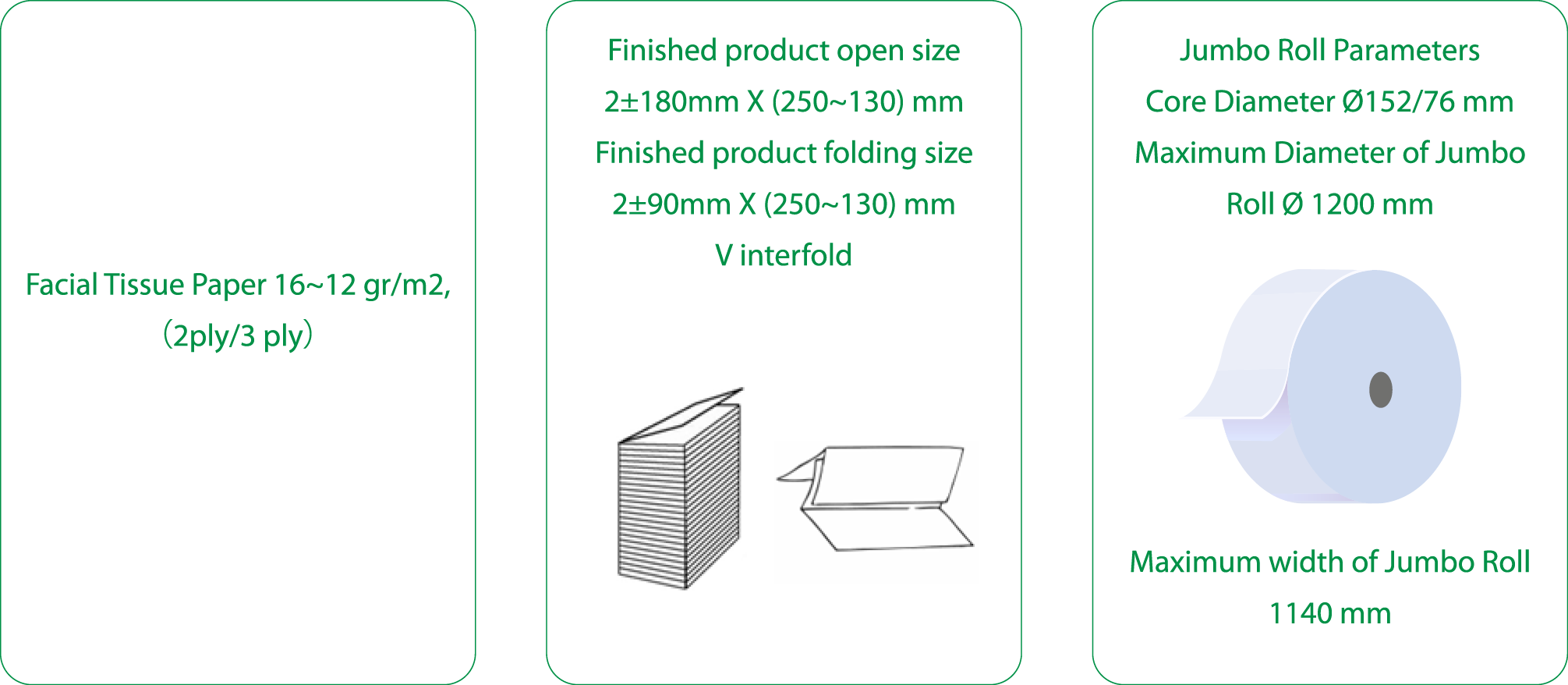

Size of folding roller :1200mm (width).

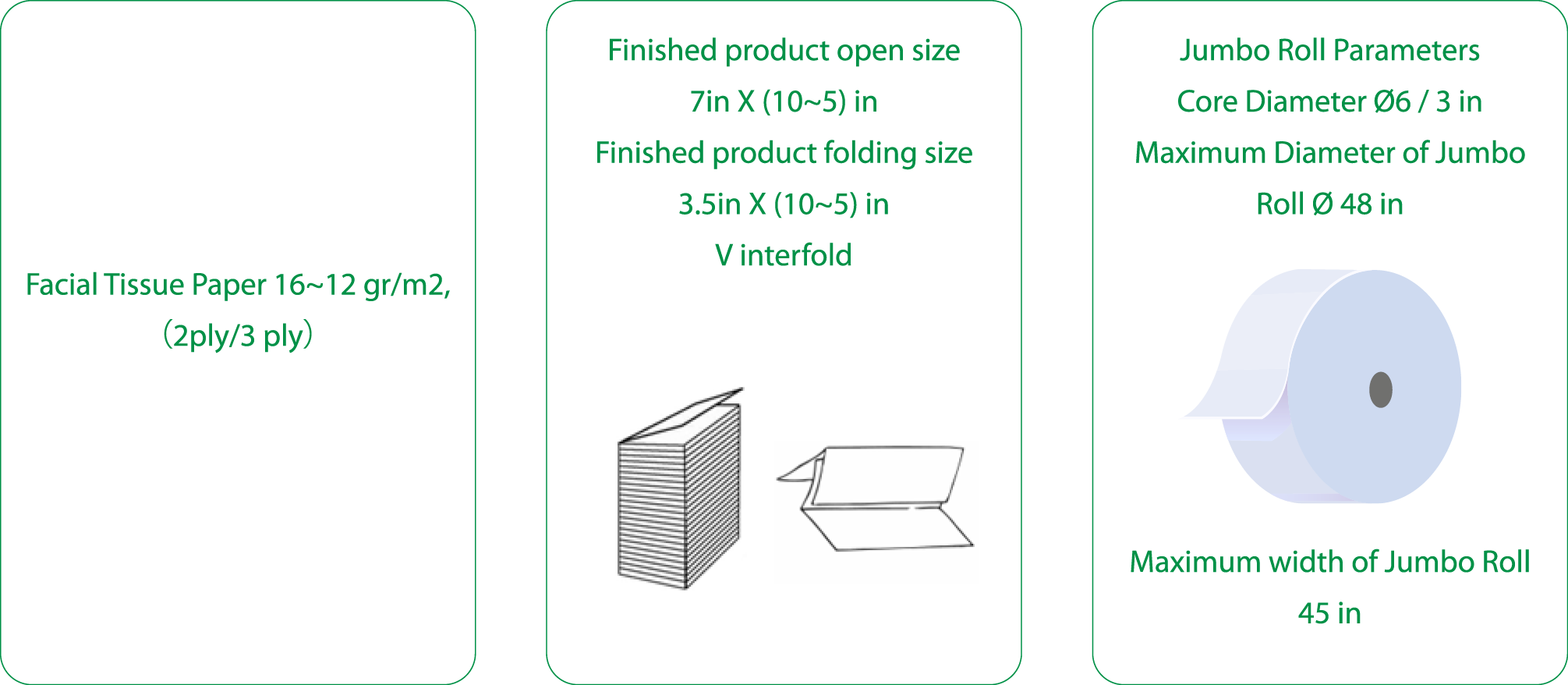

Finished product open size:180±2mm X (130~250).

Finished product folding size:90±2mm X (130~250).

Folding type: V interfold.

Capacity: 500~1000 sheets/ per min / Line.

Folding roller is used double air valve structure, material is hard-wearing steel.

Transverse paper-cutting type.

Upper blade is 1 integral high speed- steel fixed cutter front and back.

Underside blade are 3 integral high-speed cross cutters

Circular blade:3 blade front and back.

Edge embossing unit: underside cylinder is bearing steel.

8 edge embossing each front and back.

Main frame is panel structure, thickness is 40mm.

Sheet counter adjustable & Pneumatic sheets marker

Controls housed in iron cabinet

Variable speed by electronic control.

Emergency stop circuit (emergency switch off) to reduce to ruin paper, spare parts and paper roll

Start alarm lamp with beeper

Jog device

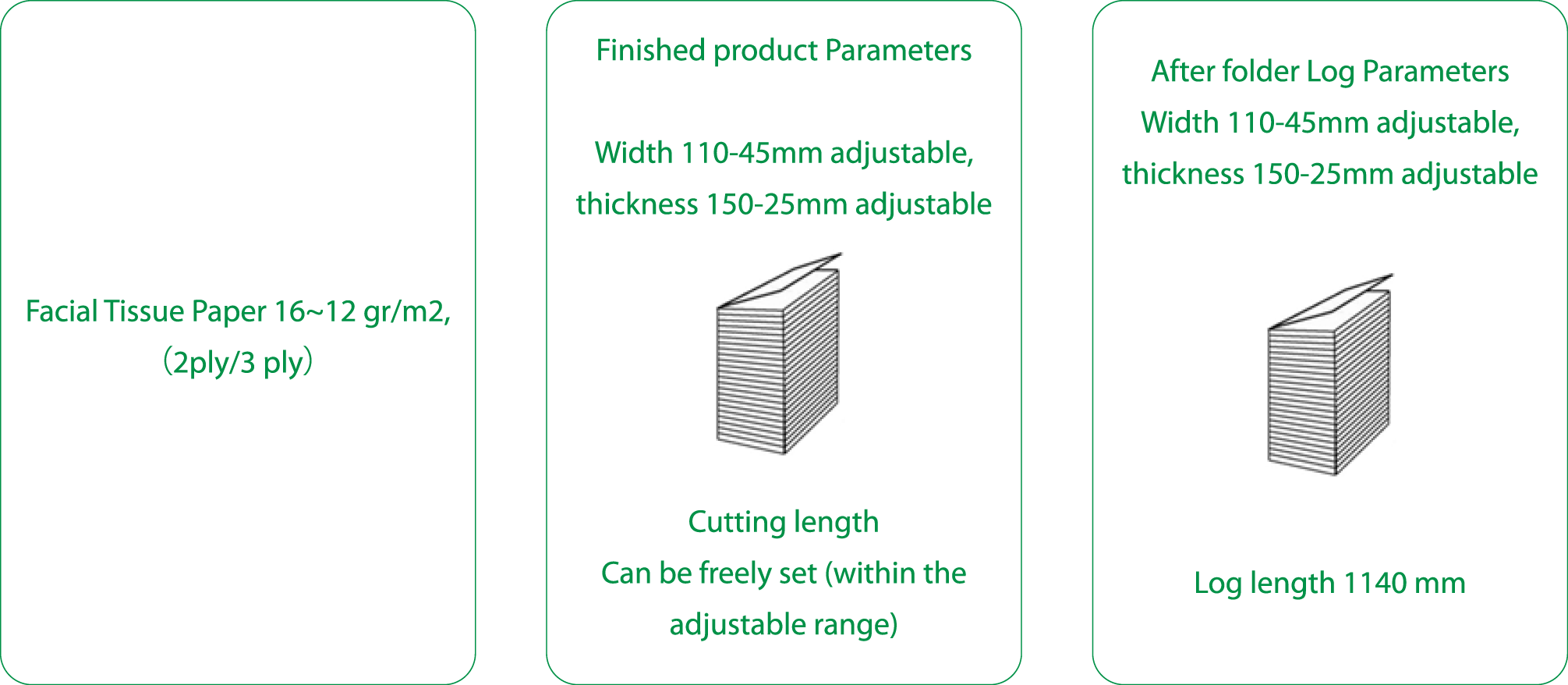

LOG SAW

Automatic length measurement and equal division without accumulated errors

Knife grinding technology from Germany ensures the quality of the blade.

Linear guide rail lifting and lowering with convenient operation and maintenance

Double frequency new technology, saving power by more than 20%.

-The production is completed through such procedures as automatic material feeding, length setting/measuring, cutting, finished products output, etc.

-PLC and man-machine interface system are adopted to flexibly change the knife grinding time, cutting speed, cutting length and the cutting efficiency is high.

-The frequency conversion speed control and servo tracking control are adopted, and the precise cutting length and flat cutting plane are realized through the optical, electrical and pneumatic integration.

- It is provided with safety protection function so that the operation is safe and reliable.

- The single passage paper cutting machine adopts cutting through upward and downward turning, so that the cutting plane of tissue is more flat, Especially suitable for tissues with height exceeding 120mm.

-The length of uncut tissue can be automatically measured, and the length of tissue to be cut can be equally divided according to the setting, avoiding length deviation caused due to accumulated error of the first or the last tissue at each row.

-The designs of removing uneven plane at the front and rear and automatically discharging scrap (especially suitable for soft drawn tissue paper packing machine) can be made according to customer requirements.

-Linked production with the paper drawing machine, automatic boxing and sealing machine, soft drawn tissue paper packing machine and other equipment can be realized.

Round knife size Φ610mm

Controls housed in iron cabinet

Variable speed by electronic control.

Emergency stop circuit (emergency switch off) to reduce to ruin paper, spare parts and paper roll

Start alarm lamp with beeper

Jog device

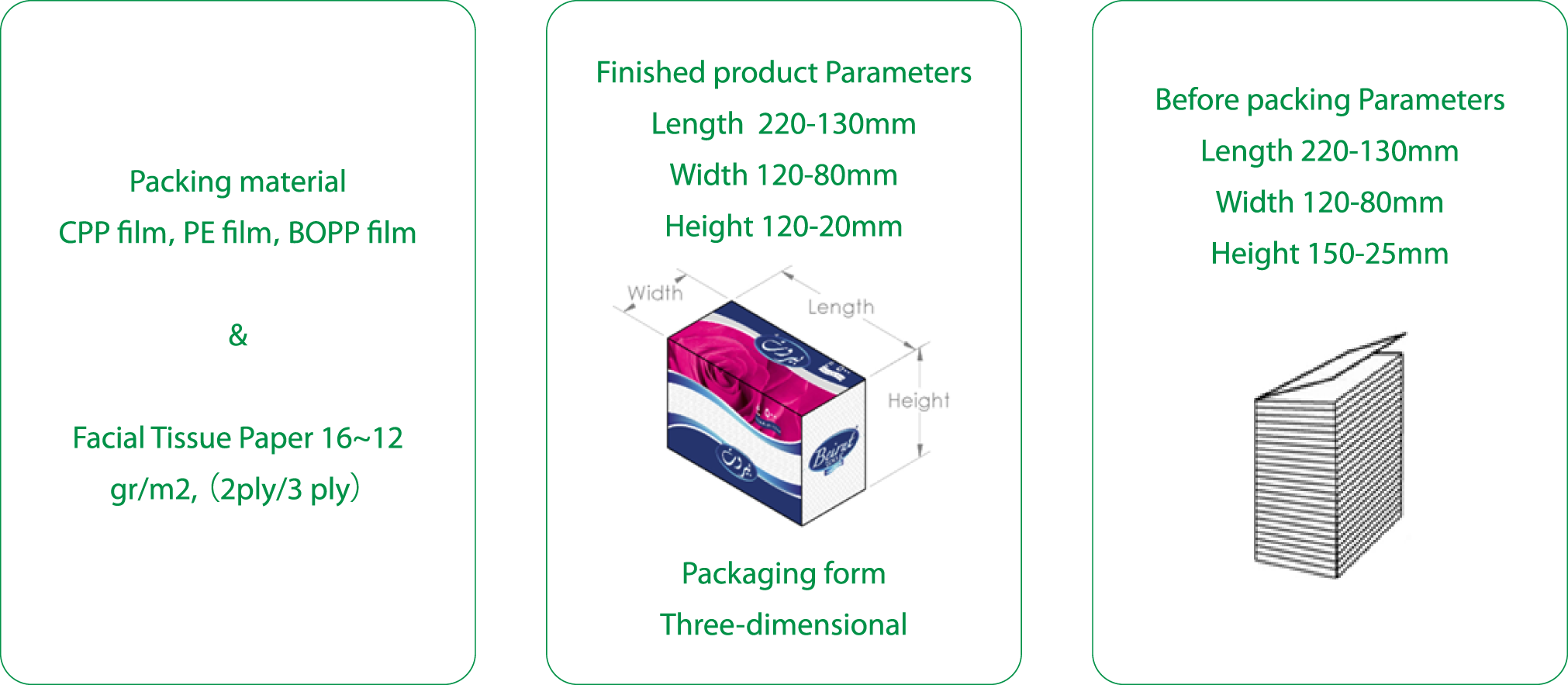

WRAPPER

Application range:

It is suitable for automatic film packing of soft drawn facial tissues, napkins, paper towels, etc.

-Packing forms such as batch No. printing (optional), tear-line cutting, film feeding, material feeding, wrapping, end sealing, corner folding, side sealing, outputting and etc. are adopted. Featured by compact structure, beautiful packing and firm sealing.

-Multi-servo motor,10" touch screen, PLC control system and man-machine interface display make operation more clear and convenient. With high automation degree, the machine is more user-friendly.

-The automatic material arranging and conveying mechanism is adopted to facilitate linked production with automatic production line, which can greatly reduce labor cost.

-The photoelectric eye automatic detection tracking system is adopted. No film movement is made if the bag is empty, so as to save packing materials to the utmost extent.

-With wide packing range and convenient adjustment, fast switching among various specifications and sizes can be realized.

-The arc and linear guide rails can be adopted to realize more stable running, lower noise and longer service life.

-All important parts are provided with the linear torque limiter and overload protector to effectively protect machine safety.

-The machine can be connected with the large orbit paper cutting machine at its front end and with the soft drawn medium packing machine, or case packing line at its rear end.