Manufacturer Details

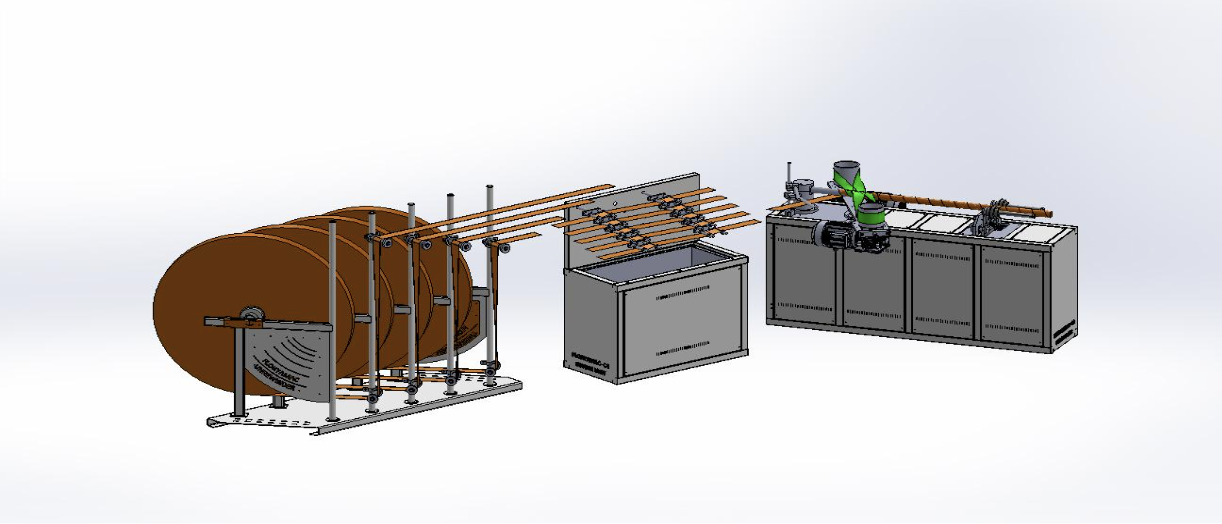

CORE MAKER

4Layers Jumbo Rolls Stand

Jumbo Rolls can be easily placed in position

Automatic gluing process with Diaphragm Pumps

Automatic cutting nonstop by free cut unite

Digital counter for Core meter

Variable speed by electronic control.

PLC touch screen control

Controls housed in iron cabinet

Emergency stop circuit (emergency switch off) to reduce to ruin paper, spare parts and paper roll

Start alarm lamp with beeper

Jog device

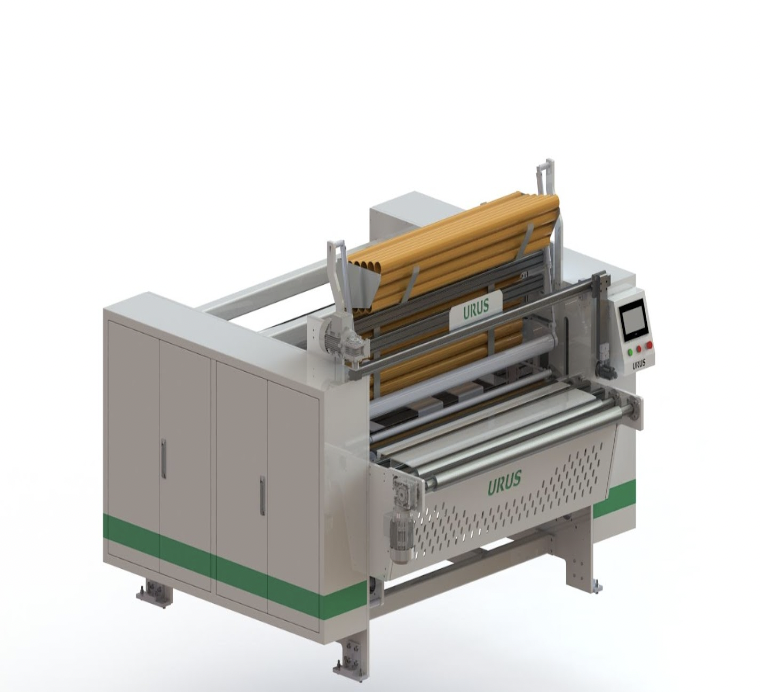

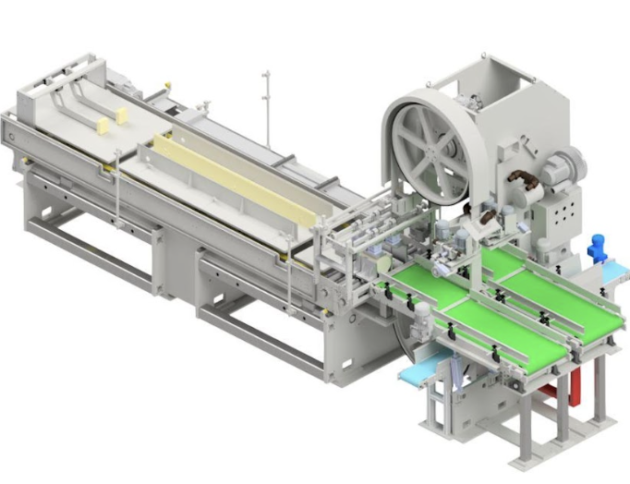

TISSUE PAPER ROLL PRODUCTION MACHINE

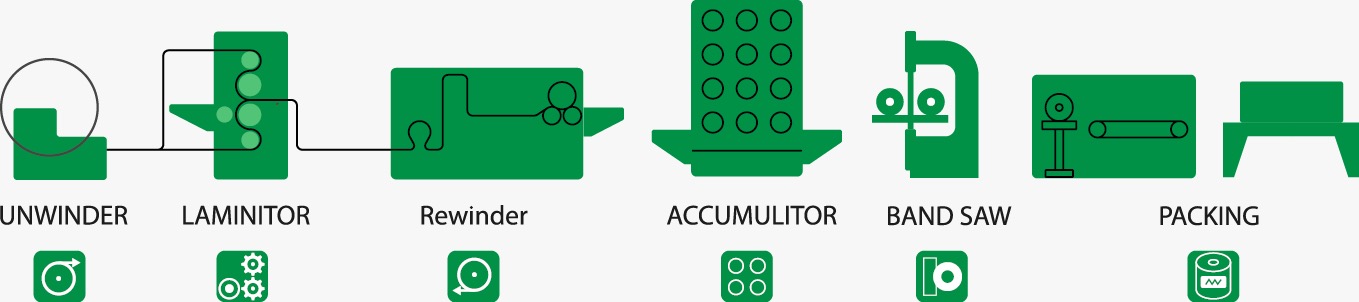

UNWINDER

Pneumatic of Jumbo Roll Loading arms lifting

Pneumatic Fixing of Jumbo Roll Shaft

Manual Jumbo Roll Centering

Pneumatic Jumbo Roll Unwinder Belt Arm

Manual tension control (Automatic Option)

Jumbo Roll Limit switch Option

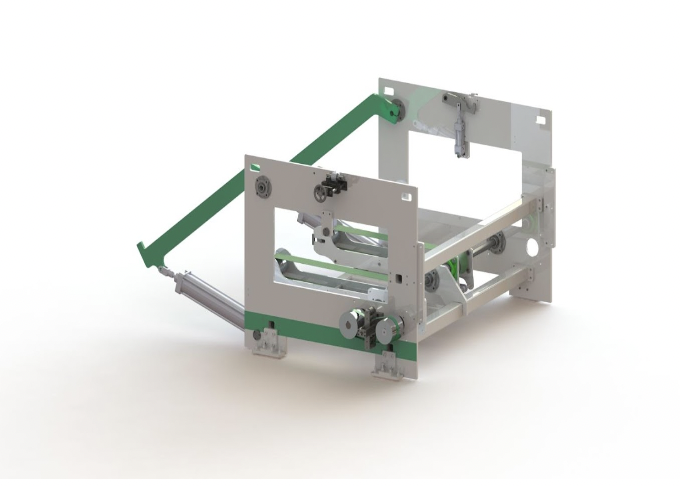

LAMINATOR

Two sets of rubber to steel rolls, especially designed to emboss laminate the paper to match the samples submitted by the customer.

One marry roll to press the design over the second ply to bond the two-ply together

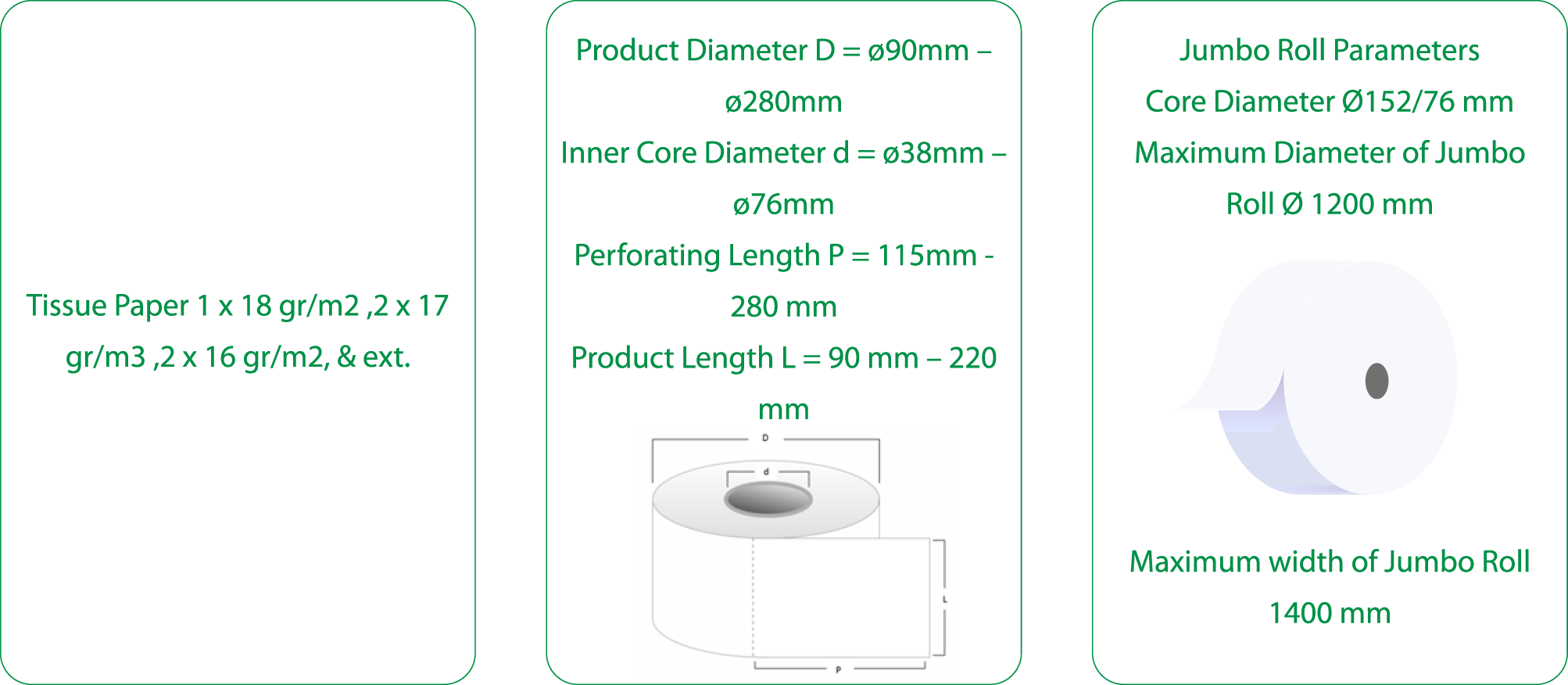

Glue Maximum width 1400 mm

Pneumatic İn-Press Out-Press

Ceramic Anilox cylinder

Glue Dr.Blade ragle system (Chamber System)

The glue application unit will be complete with the fountain roll, driven by a gear, glue transfer roll, a stainless-steel glue pan with cover.

Mixer system to prevent paint from drying (option)

Manual Embossing Register Control adjustment

Customized Point To Point Embossing pattern

Chrome Plated Embossing Cylinder

Laminate Speed 200 m/min

REWINDER

Mechanical Rewındering system

İnFeed cylınder rollers

Spiral Perforating cylinder 2 anvil Blades

Perforation length, adjusted by gear

Slitting unit (Option)

Automatic Carton Core Feeder

Carton Core Accumulator Load 20-30 units

Automatic Log out exit

Automatic final cutting

Automatic Edge Gluing For Log

Final Automatic Rotation For Log

Paper break monitoring system, process is stop automatically.

Digital counter for roll meter

Variable speed by electronic control.

PLC touch screen control

Controls housed in iron cabinet

Emergency stop circuit (emergency switch off) to reduce to ruin paper, spare parts and paper roll

Start alarm lamp with beeper

Jog device

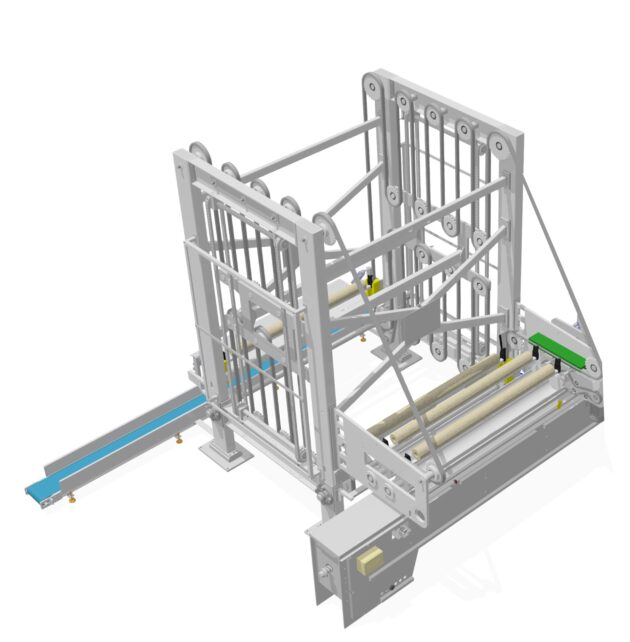

ACCUMULATOR

BAND SAW

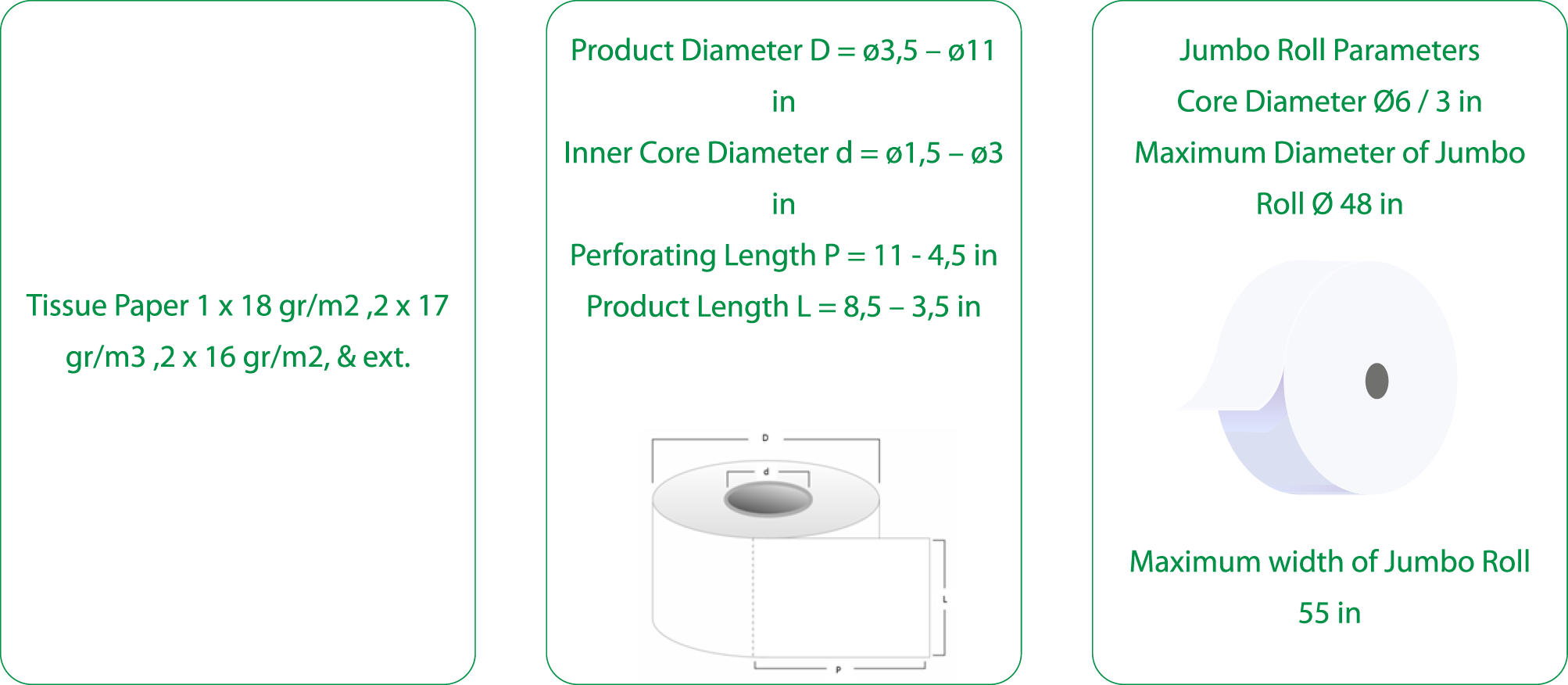

Specification of finished product (Large cutting range): Toilet or Kitchen roll

PLC touch screen control

Log pusher controller by a servomotor, which provide the correct cutting length

Single stainless steel feed channels separate servo motor control with clip hold the rolls

Automatic adjustable blade sharpening system

Automatic stop in case of misplacement or over ø of log

Band saw knife wear and tear less than log saw cutter

Adjustable cutting speed and length, so the smoothness and continuity of pushing, cutting

Can be cut the roll with core or without core, cutting tolerance less than other cutting machine, finished production with perfect cut.

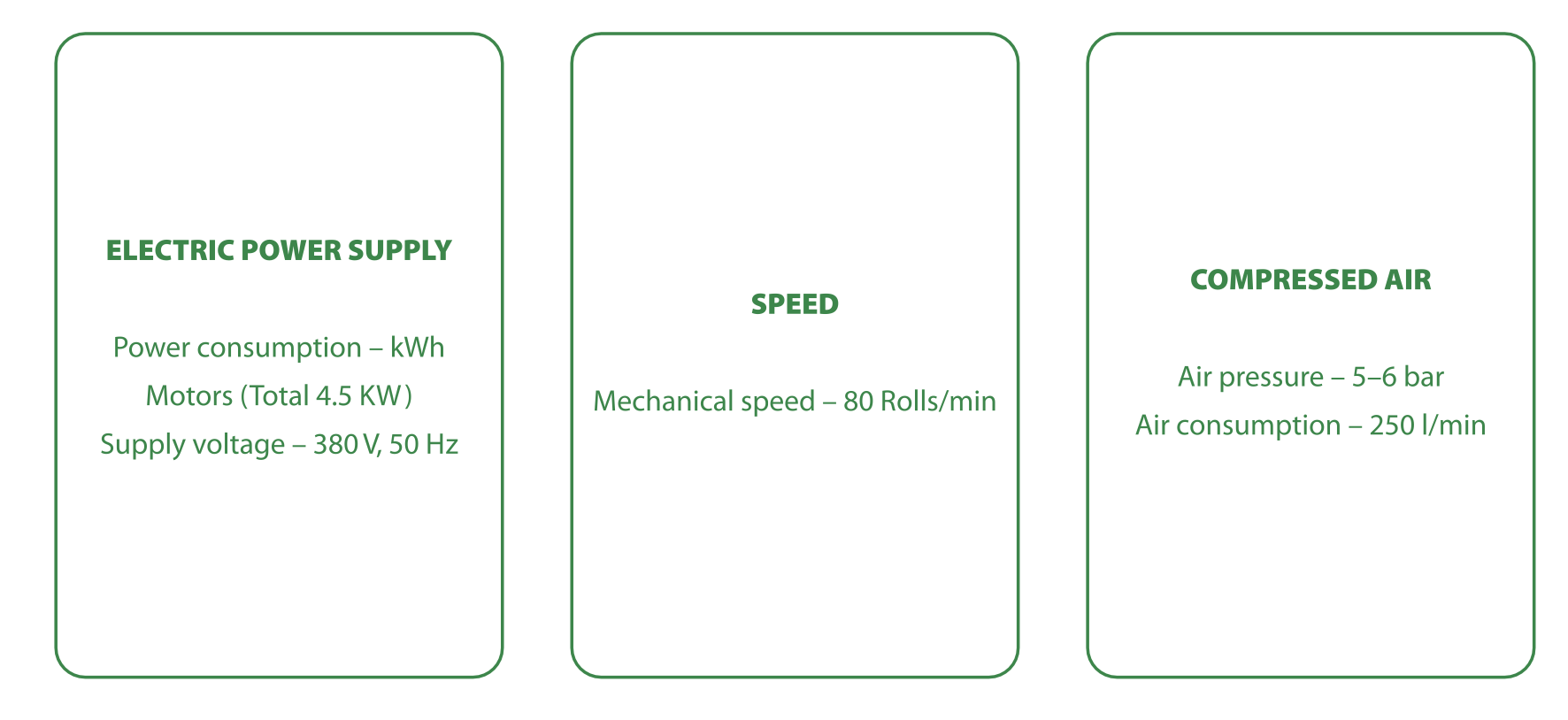

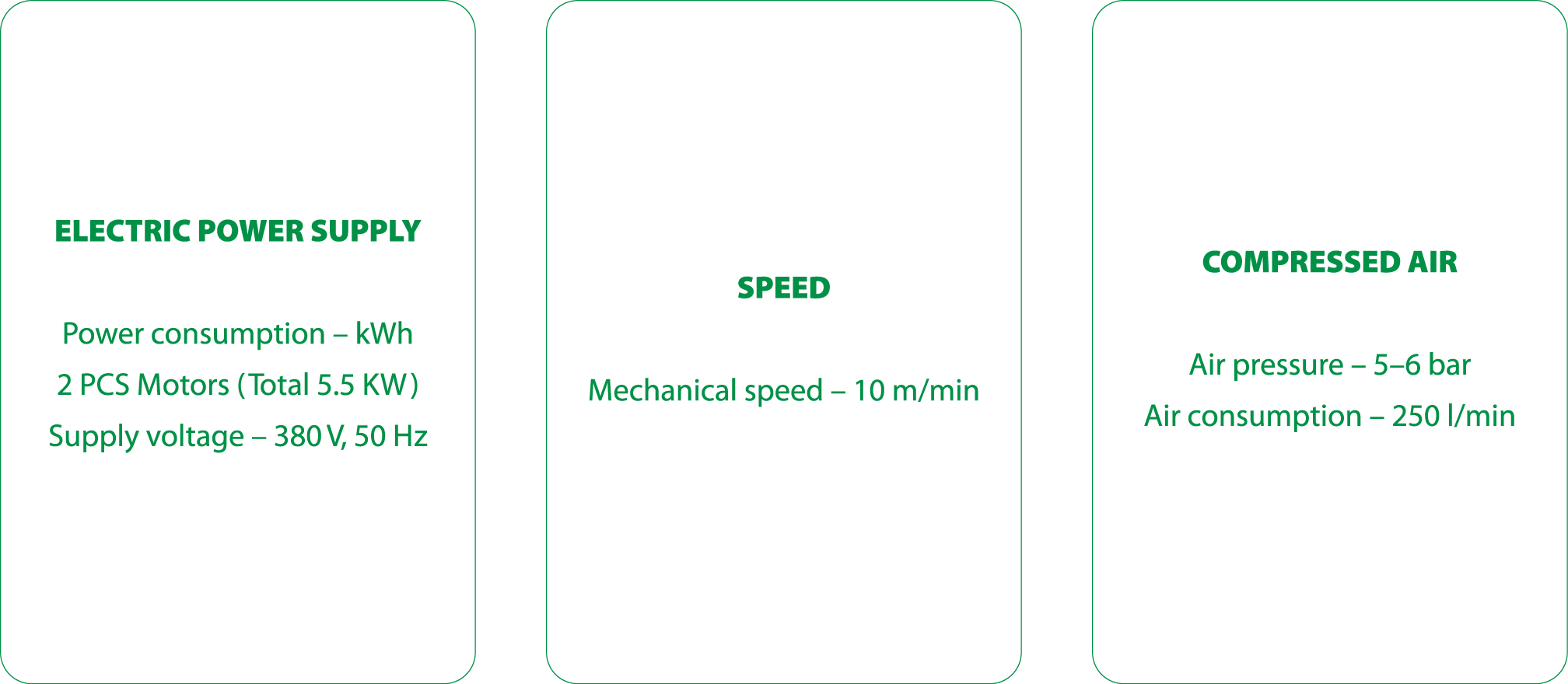

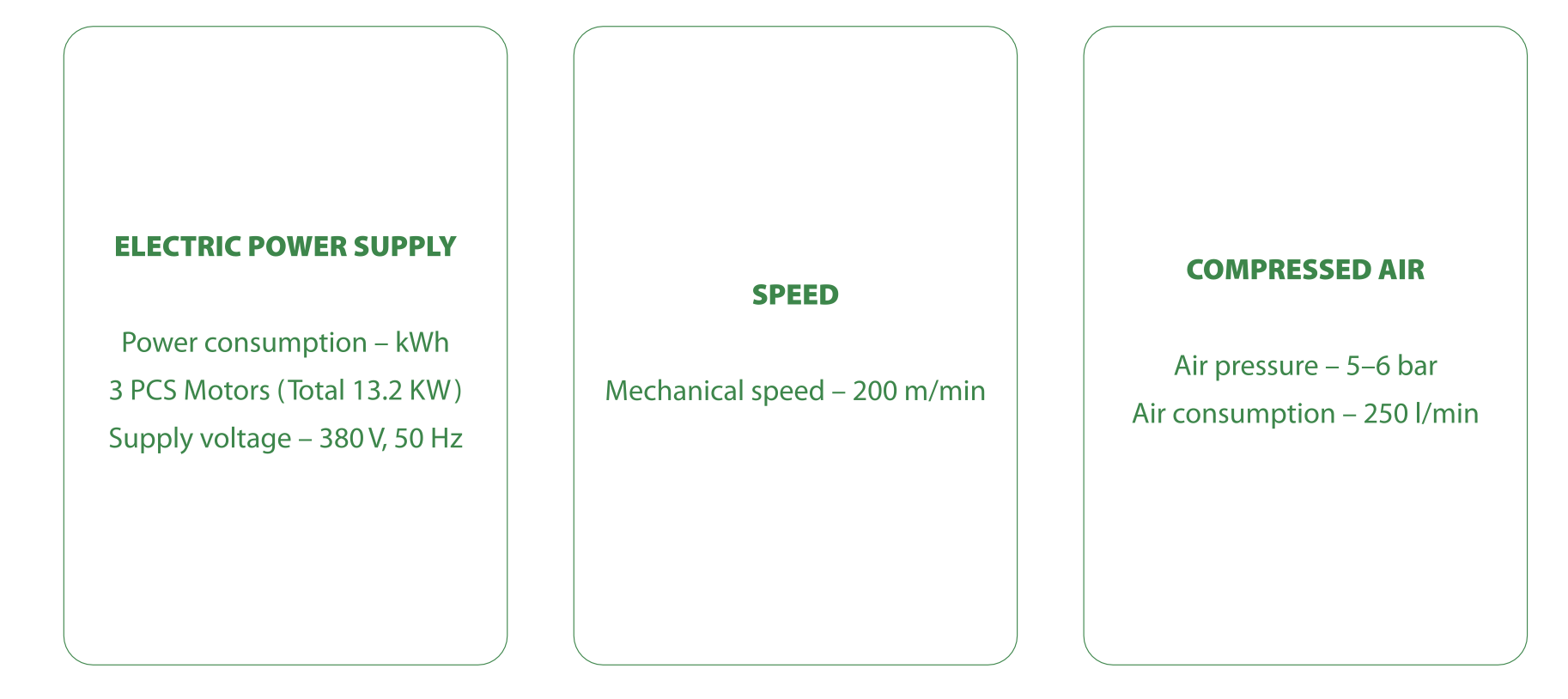

Technical Features:

Paper log length: max3000 mm. (to be specified)